The Virtual Transition

Previous to the COVID-19 pandemic, the inventory at each location was tracked by physically checking, counting, and scanning each individual piece of product. When the pandemic hit and out of state travel was not an option our inventory team had to adjust the way that they preformed their inventory counts. This meant transitioning to a virtual version of their normal inventory.

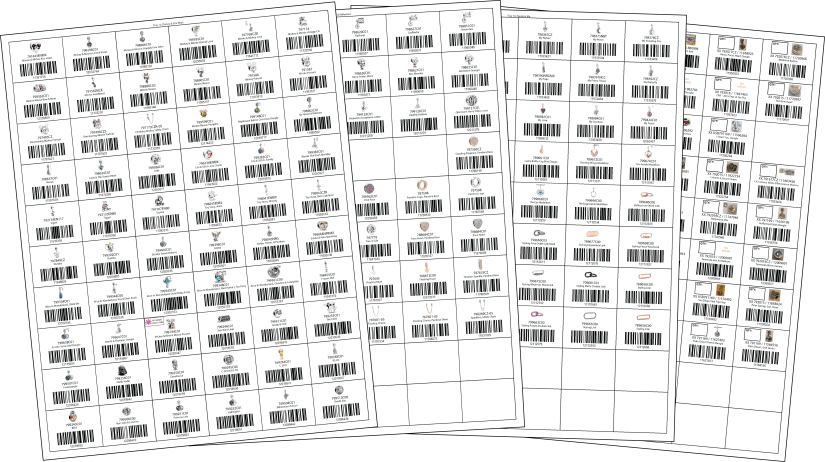

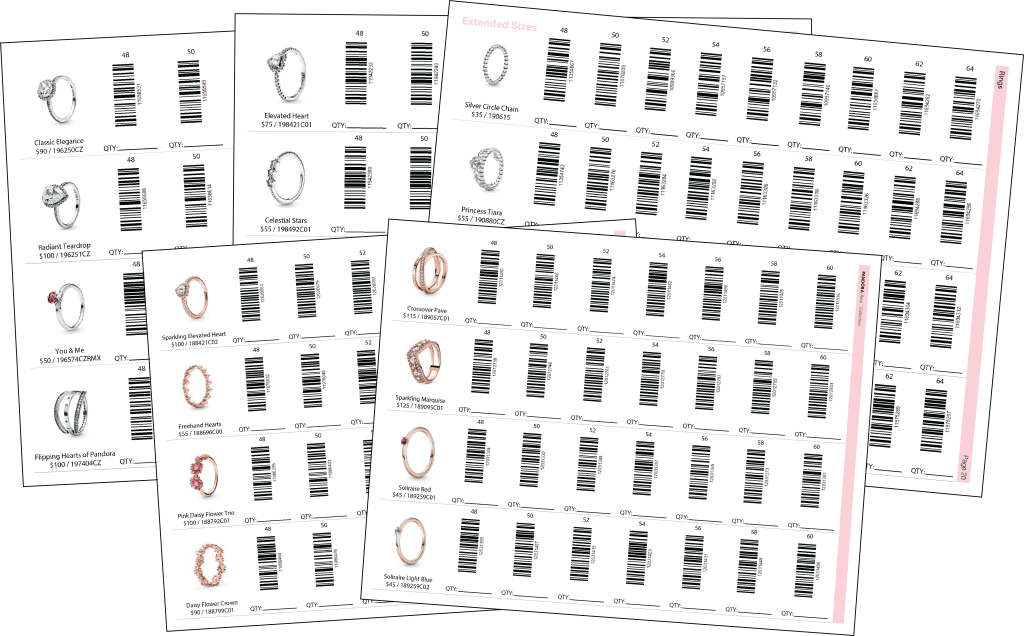

I took the lead on the project and worked directly with the inventory team to create planograms that the retail locations would fill out with their inventory counts. Once these were collected the inventory team would scan the sheets into the system and record the locations stock.

Previous to the pandemic, an inventory check at a retail location that was fully prepped with minimal mistakes would take upwards of 4.5 to 5 hours to just scan and check the product. With the new planograms, virtual and non-virtual inventory checks have been reduced by 1-1.5 hours per store.

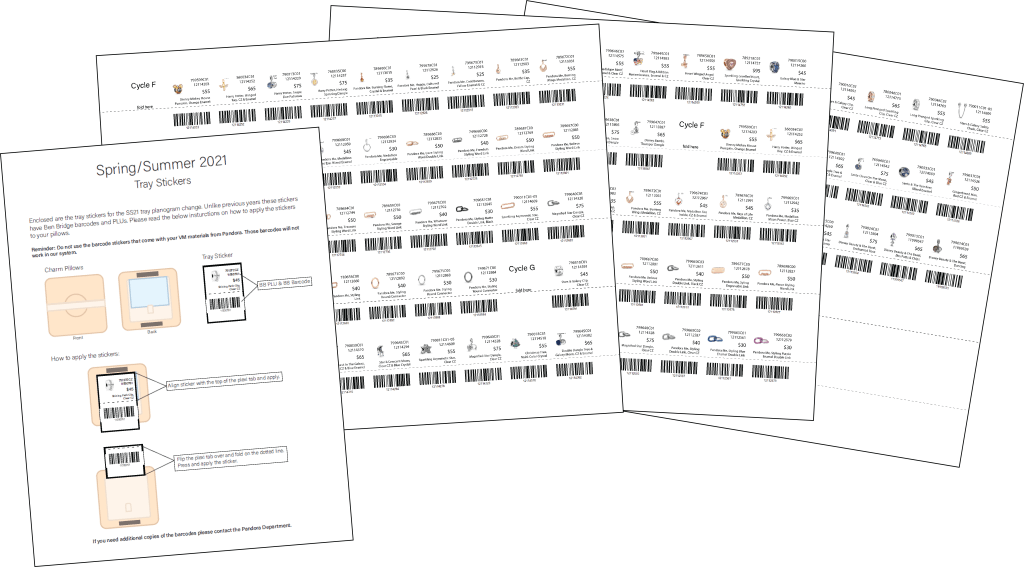

Due to the fact that I was already making barcode planograms for our inventory team. I researched and found a way to make stickers to place inside the trays that house a majority of the product at the stores. This is to help the stores stay organized by ringing up sales correctly and keeping track of their inventory throughout the year.